Particularly demand for HDPE Bag Packaging has increased in retail, agriculture, food and beverage, and medicines. HDPE bags have choice for packaging not only because of their affordability, toughness but also adaptability. Establishing a business producing HDPE bags offers a chance to get with lots of potential for expansion and creativity. It covers a topic such as equipment setup, marketing strategies, business planning, market research, and production processes.

Market Size :-

HDPE packaging is becoming to have a global market size of USD 17.10 billion in 2022. USD 17.96 billion in 2023, and USD 26.25 billion by 2030.

Scope of business :-

Various sectors utilize HDPE bags to package goods, such as electronics, groceries, textiles, chemicals, pharmaceuticals, and more. Producers of HDPE bags can meet diverse client needs and serve different market segments.

Raw material required :-

HDPE resin is the important ingredient used to make HDPE bags. Antioxidants, UV stabilizers, slide agents, anti-block agents, and colorants are examples of ingredients. Not only Colorants Pigments but also dyes can be added to provide the required color in colorful bags. Especially in case of printing, the solvent or carrier is a solvent or ink carrier may be required if printing is desired on the bags.

HDPE Bag Manufacturing Start up what you need to know

1)Market research

2)Analysis of Competitors Business,

3)Equipment, machinery, and raw materials,

4)Promotion and Identity Environmental Aspects to Take into Account Client Support.

5) Government policies, rules and regulations for manufacturing HDPE bags.

Market demand

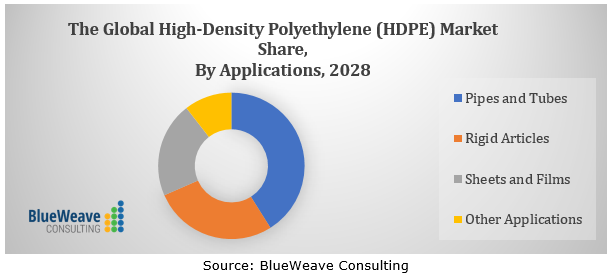

Between 2023 and 2031, the global market for HDPE is expected to grow at a significant rate. The market is undoubtedly expand beyond the estimated horizon in 2022 due to the constant growth rate and increasing adoption by major players.

Future Potential :-

A number of factors are likely to have an impact on India’s ability to manufacture HDPE woven sack fabric and bags using circular looms in the future. These could include alterations in the regulatory growing, shifts in customer preferences, and technological breakthroughs. It should be noted that Global trends like digitalization, automation, and sustainability may also have an effect on the sector.

Machinery and Equipment :-

The following components contain the machines:

1)Unwinding-Printing Stations-Rewind Station-Drying Bridge-Drying Chambers.

2)To ensure a long and effective machine life, firstly the stereo rolls, secondly anilox rolls, and thirdly impressions cylinders can be used.

3)Woven sack bag making machine,

4)Jute sack bag making machine,

5)HDPE PP Tape Plant,

6) Bobbine Cleaning Machine

Can we get funds from the bank for HDPE bag making business :-

It is advantageous to obtain bank financing to launch a firm producing HDPE bags. Here are a few typical choices that you may think about:

1) Small Business Loans: A lot of banks provide small business loans for company owners to launch or grow their enterprises. Such loans not only require collateral, a strong business plan, but also a clean credit history.

2) Microloans: Microloans are smaller loans not only aimed at startups but also aim at small businesses that are also provided by certain banks. Without a doubt when it comes to regulations, microloans frequently have less restrictions than formal company loans.

3) Credit lines: Apart from this a credit line might give you flexibility in how you handle the money for your company. Up to a predetermined amount, you can borrow, pay it back, and borrow again as needed. For controlling variations in cash flow, this can be helpful.

4) Government-backed Loans: Without a doubt Government-backed loan programs that assist small enterprises may be available in your area. These loans frequently have more affordable interest rates and advantageous terms.

5) Equipment Finance:- Further more if you require money especially for buying equipment for your HDPE bag manufacturing company. With this kind of financing, access the required apparatus while spreading out the expense of the equipment over time.

Case study of HDPE bag making business

Green Tech Packaging, located in remote area specializes in manufacturing HDPE bags. Founded by environment lover Emily and Mark, the company aims to fullfill demand for renewable packaging options in the community.

Using their expertise in renewable practices and engineering, they established Green Tech Packaging to offer environment friendly alternatives to traditional plastic bags.

Through market research, they identified increasing consumer awareness and regulatory pressure for renewable packaging solutions. The company also provided premium HDPE bags made from recycled materials.

By aligning with the environment lover customers and offering eco-friendly choices, company has gained attraction and earned positive feedback from stakeholders and clients alike in the competitive packaging market

HDPE bag making business are good for health or not ?

The health and safety of an employ HDPE bag manufacturing company may be affected. Define workplace safety, by following guidelines, such as hand hygiene, gown, mask, eye face protection.

Not only use gloves but also putting controls to reduce chemical exposure. Chemicals used in the production process, such as resins as well as dyes, might be hazardous to your health if not handled correctly.

Furthermore, it is important to tackle ergonomic issues in order to reduce the likelihood of musculoskeletal disorders in employees

Without a doubt the environmental impact of incorrect HDPE bag disposal, which can indirectly damage human health by causing pollution.

To reduce the health risks follow regulations to improve workplace safety, chemical handling, waste management, and environmental protection is crucial.

If you are thinking to start HDPE bag making business, what are the chances of success ?

Understanding the dynamics of the market demand and competition is important for success. The market for HDPE bags, starts from environmentally friendly packaging options.

It should be noted that In order to stand out in a crowded market, offer distinctive value like personalized designs, eco-friendly materials, at affordable prices.

The significance of operational efficiency lies in its emphasis on optimizing resource use not only supply chain management, but also use streamlined manufacturing processes.

For long-term survival, proper capital management and capital acquisition are essential components for financial planning.

Products marketing strategies for HDPE bag making business :-

1) Determine Your Target Market :- Focus your marketing efforts on industries including manufacturing, food & beverage, retail, healthcare, and hospitality.

2) Online Presence :- Keep up a polished website that highlights your goods, services, and core principles.

3) Social Media Marketing :- Use sites like Instagram, Twitter, and LinkedIn to interact with influencers in the industry, publish product updates, and establish connections with customers.

4)Collaborations and Partnerships :- Look into forming alliances with companies that complement your own, such merchants, environmental organizations, or providers of packaging.

5) Direct Sales and Networking: Make direct contact with prospective customers by using direct sales strategies.

6) Customer reference and Case Studies: Emphasize how your HDPE bags have assisted to overcoming packaging obstacles, cutting expenses, or enhancing environment friendly procedures.

Hire and Train your team

1)Describe the duties and roles of the jobs :- Determine machine operators, quality control inspectors, production supervisors, sales representatives, and administrative staff, include these department in company.

2) Find Qualified Candidates: Make use of a variety of channels, such as social media, industry-specific websites, online job boards, and professional networks, to draw in qualified applicants.

3) Give Training: Instructions should address corporate policies, quality standards, machine operation, safety procedures, and product requirements.

4) Safety and Compliance :- Assure that every team member is knowledgeable about safety procedures, emergency protocols, and observation to occupational health and safety laws.

5) Team Collaboration and Communication: To encourage accountability and ongoing development, hold regular team meetings, feedback sessions, and performance evaluations.

6) Track Performance and Offer Feedback :- To inspire and enable your team, offer helpful criticism, mentoring, and praise.

Market Your brand :-

1) Create Brand Identity :- Develop a firstly distinctive brand name, secondly logo, and finally visual design that accurately conveys the goals, beliefs, and dedication to sustainability and quality of your business.

2)Describe Special Value :- Determine the special qualities and advantages of your HDPE bags, such as their affordability, eco-friendliness, customisation possibilities, and durability.

3)Choose the Correct Audience to Target :- To determine who your target market is, conduct market research. This will include companies in sectors firstly manufacturing, secondly food and beverage, thirdly retail, fourthly healthcare, and finally hospitality.

4)Make Use of Several Marketing Channels :-To promote your items and interact with customers, have a strong online presence on social media, your website, and online marketplaces.

5)Customization and Quality of the Product :- showcase your HDPE bags features, strength, and personalization choices with attracting product design.

HDPE Bag Making Business Plan :-

The goal of these business plan is to provide premium, customisable HDPE bags as a means of entering the market. The marketing campaign highlighted the product’s quality and environment friendly features as well as its unique value suggestion. Aim to increase brand awareness, catch clients, and create connections by utilizing a mix of direct sales, internet marketing, and attendance at trade shows. Furthermore, put the needs of the client by offering outstanding support and service, which will boost sales and achieve long-term success in the cutthroat packaging sector.

Conclusion :-

The industry that produces HDPE bags is well-positioned to satisfy the rising demand for environmentally friendly packaging options. Establish a strong market presence and reliable partnerships. Offer eco-friendly packaging solutions due to dedication to quality, innovation, and environmental responsibility. Aim for growth, profitability, and long-term sustainability in the evolving packaging industry through strategic marketing and operational excellence.